Timor-Leste has been our top priority since 2018.

Following 25 years of conflict that claimed 200,000 lives and destroyed all infrastructure, Timor-Leste became the first new independent state of the 21st century. Today there are about 1.3M people living in Timor-Leste, and poverty remains widespread; almost half of the children under 5 years old suffer from chronic malnutrition, a statistic that hasn’t improved in 20 years.

Over 90% of the country’s income comes from oil and gas, but this revenue stream is running out.

Timor-Leste is the most oil-reliant nation in the world.

Current oil production is winding down.

The petroleum fund will likely run out in an estimated 10-14 years.

Improving the coffee sector is of critical importance.

Coffee is the second-highest earner for the country after oil.

37% of households depend on coffee for a portion of their income.

Productivity is currently unreliable and extremely low, about 1/5 that of Colombia on average.

Profitability is currently low and volatile for all actors along the supply chain, from pickers to exporters.

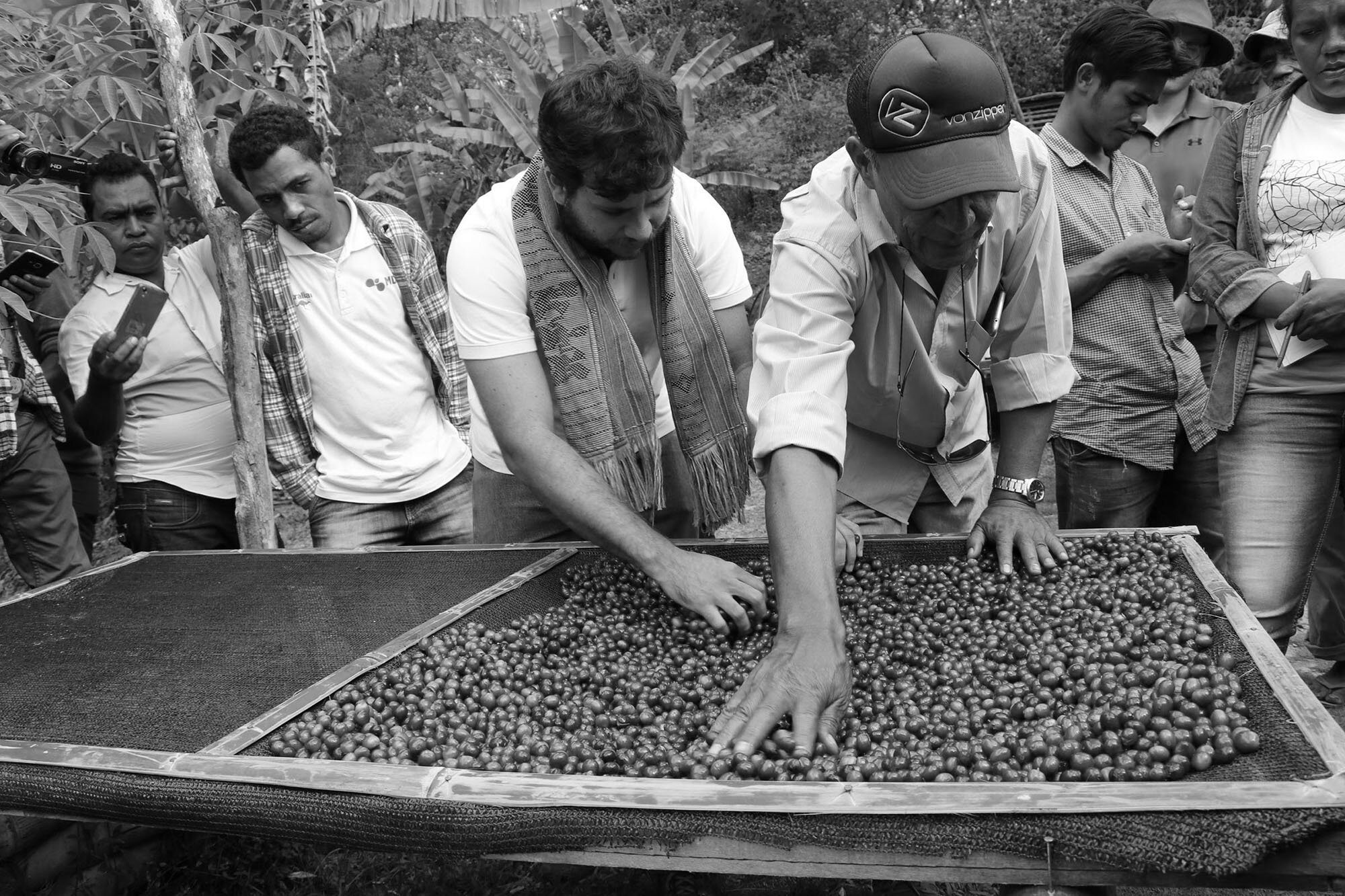

Producers attending training sessions with Miguel of RM Colombia

“Timor-Leste’s competitive advantages and disadvantages all point to one future: higher value from price differentiation or specialty coffee.”

Our strategy to improve the total value and profitability of the coffee sector is familiar, and due to Timor-Leste’s small size and the collaborative culture, we are also able to include top-down, national-level methodology that is impossible in other countries. Here we partner with governments, development banks, and other institutions alongside our usual community-led production plans.

Ameta collecting cherry in Ermera

Wet mills and drying stations

We are building new cherry processing centres each season, expanding a network of farmers now producing award-winning coffees, and exporting over 90% of the output at prices 2-3X the national average.

Video training guides

We collaborated with the Market Development Facility and Asian Development Bank to produce a custom 11-part video guide outlining coffee production best practices in both Tetun and English.

Producers attending training sessions with Miguel of RM Colombia

Coffee game show

Shown on the local TV network, this was designed as a way to make high-quality production practices common knowledge. You can watch Ameta and Miguel in the English version here.

Cupping labs

We are currently building the first cupping lab in Atsabe village. This will be the first of many quality management and information hubs run by local women. Our goal is to replicate the success of this model observed in Colombia.

Breakdown of a typical price paid for coffee from Timor-Leste

Figures are displayed in USD/kg. All values have been converted to green bean equivalent (GBE) at 0,20 prep.

In 2020, our average yield of green coffee from cherries (washed, honey and natural processes) was 14.48%. For washed coffee our average yield from parchment to green coffee was 66%.

Click to expand and learn more

Raimutin Wet Mill

Suco Baboe Kraik

Atsabe, Ermera Municipality

Transitioning from gathering to active farming

In early 2018, we met with groups of producers in villages across Atsabe to hear about how the coffee market has served them in recent history. Though there was no immediate consensus on the cost of production, most stated that the price they received for cherries was too low for there to be any profit for investment in coffee (pruning, fertiliser etc), that as a result, they were working in a gathering style rather than active farming.

Those with farms larger than 1Ha explained that the main cost they have each year is hiring help for a few days to pick cherries at a day rate of 3-5 USD. If they pay any more than that, the cost is higher than revenue. Along with volumes and a few more data points, this gave us a rough idea of the baseline cost of production to work from, and a target for profit improvement.

Together we developed a plan for a prosperous future through by systematically solving the diverse challenges laying along the path to selling in the specialty market; financial, legal, technical etc. The first steps included building a community wet mill. Three years on, hundreds of families connected with the Atsabe community wet mill generate at least 75% more profit from coffee compared with selling the old way.

The next phase is investment in productivity and scaling up while maintaining quality.

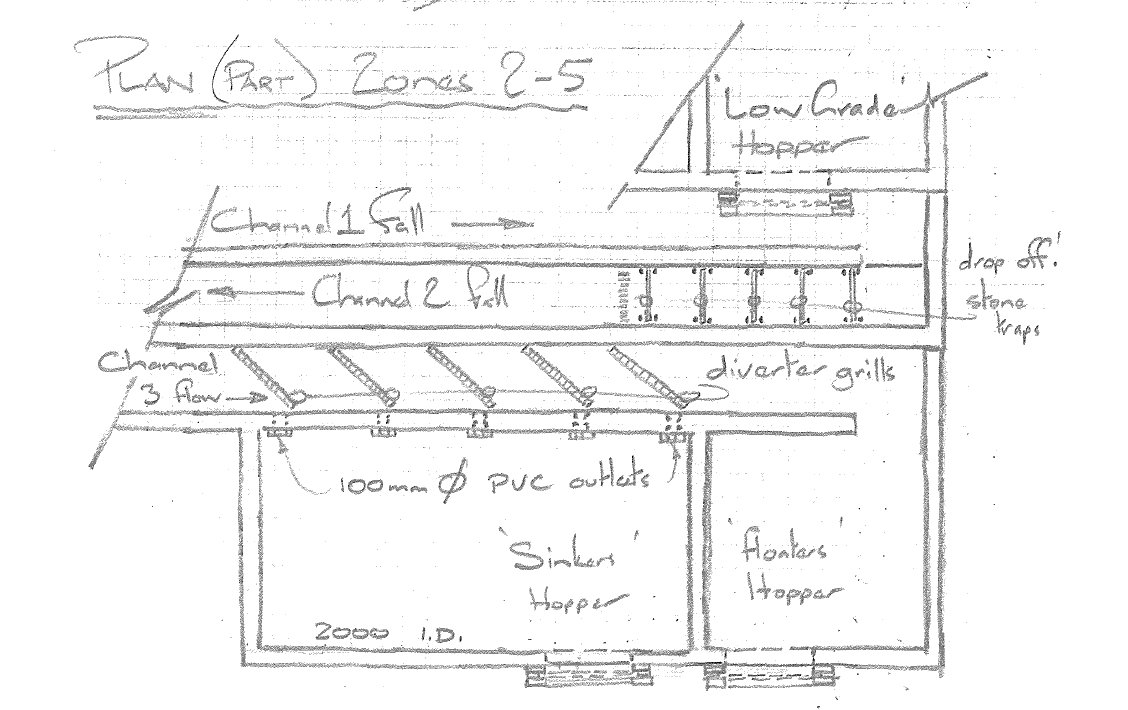

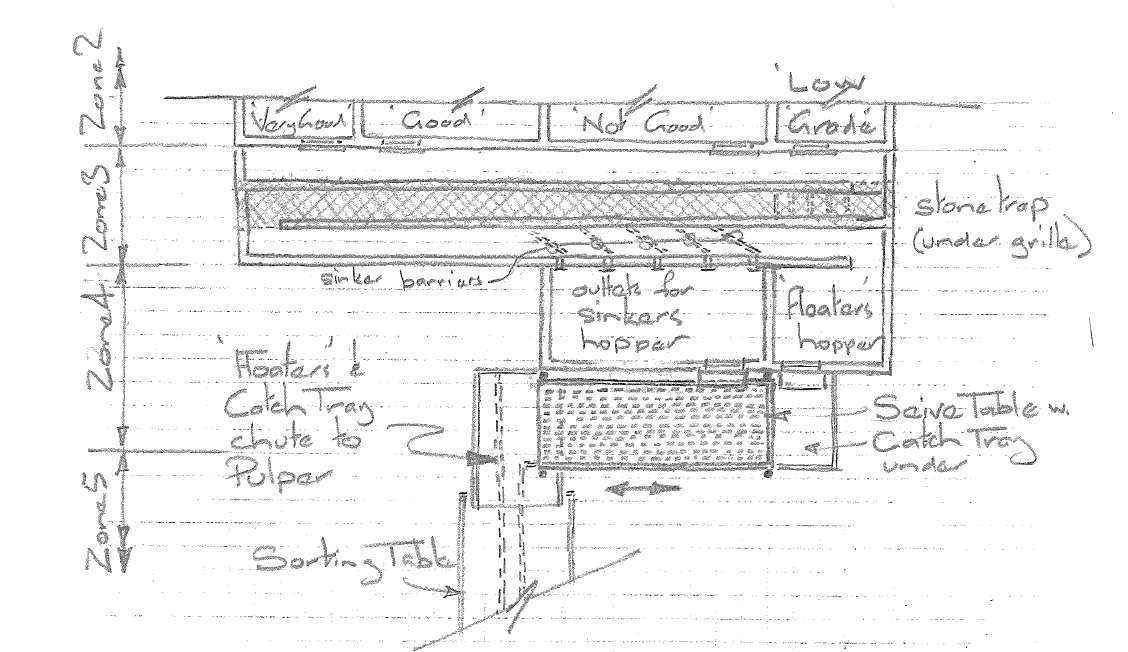

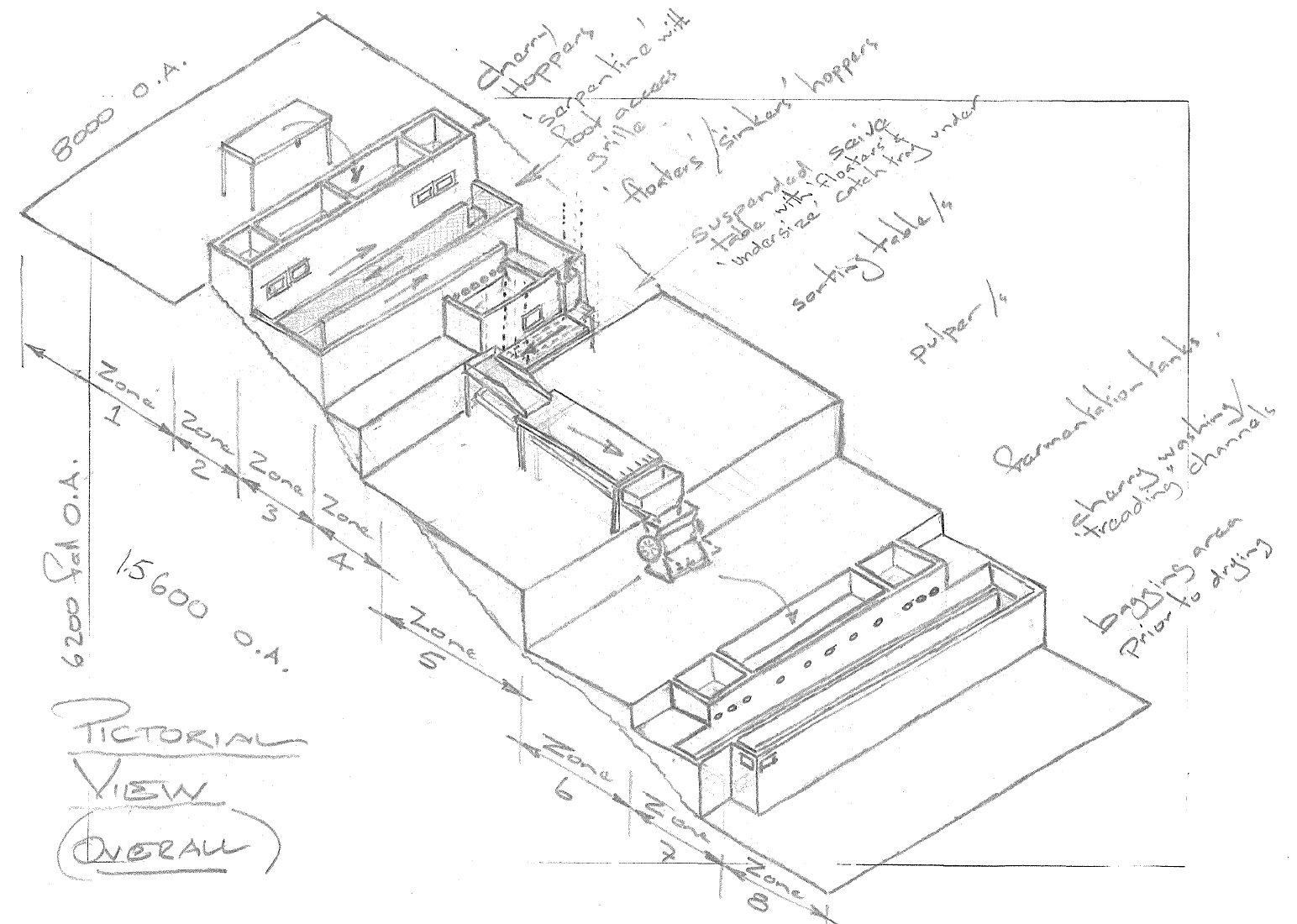

Raimutin Wet Mill, Atsabe District

All designed in-house, this processing centre uses gravity to move coffee through stages; no double handling, no unnecessary machinery. We drew upon our experience working in many other coffee-producing countries to combine elements that would most likely improve Ermera’s coffee quality given the unique set of challenges facing the region.

Each section of the plan uses materials that are local and readily available. We used only standard shapes and dimensions already found in the construction of the local houses, to make replication easy and likely.

Raimutin wet mill blue prints

Parami

-

1800 MASL

Ermera Municipality

We are excited to offer a selection of natural and honey processed lots from the suco of Parami. Cherry from Parami, and the nearby 1800 MASL neighbourhoods Motalala and Koileki, is collected daily and processed at the Raimutin wet mill in Baboe Kraik.

Ameta and Marta Baros de Fatima

Malabe

-

1500 - 1700MASL

Ermera Municipality

Lunch in Malabe village

Home to the production of fantastic naturally processed coffees and the purchasing of cherry processed at the Raimutin community wet mill.

Zachael, the village chief has been an ambassador for the future of Timor-Leste specialty coffee when discussing the new and a hard to envisage future systems with neighbouring village chiefs and farmers. Coffee here grows in the forests; shaded, untouched, and organic by default.

Learn More About Timor-Leste